Just over a month ago I was in England, visiting my friend Katie. The trip was amazing, and we visited all kinds of great places, many of which had a crafty theme to them. In fact, I saw so many craft related things that they'll get their own blog post. But one particular part of the trip deserves a post of its own.

While I was in the western part of England, I got to visit where Katie works. Going to someone's workplace might not always be exciting, but in this case, it was. Because Katie works at Blacker Yarns, which is part of the Natural Fibre Company in Cornwall, England.

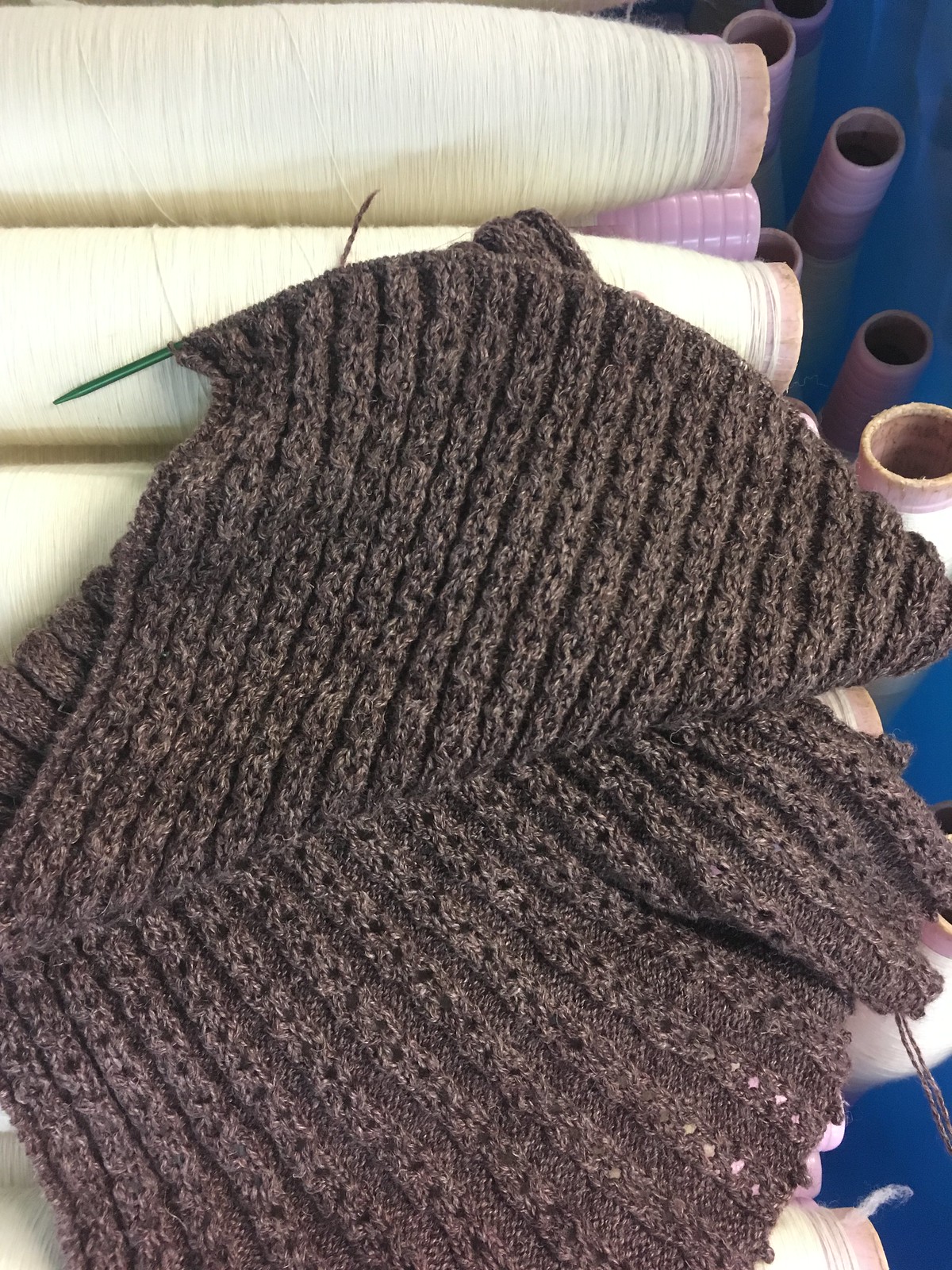

They made the beautiful yarn in my latest knitting project that's pictured above (more info about that soon!), and I got to tour the mill where they do this. It was loud, it smelled like wool, and it was magical. Let me show you around...

As soon as I stepped through the door from the offices to the mill area, I was met with bags full of wool, ready to be processed. These fleeces come in big bags and bigger bags. The Natural Fibre Company works with suppliers in different ways and from different areas, but it's mostly local fiber.

If you didn't already know, fleeces from sheep aren't just fluffy beautiful wool. They come with a lot of debris and bits that just aren't suitable for yarn. So they get hand sorted. What a job! You can see some of the rejects on the floor. Plus a trash bin that has collected a number of wooly pieces!

Sorted wool goes on the carding machine, which processes it, leaving it in long, thick sections that look like roving ropes. If you click the lower image above, it will load the video of one of the machines working.

The processed wool "ropes" are then spun. I didn't get to see this part actually working, but I did spy some cones and spools of single ply wool!

Spun wool is dyed (sometimes...Blacker Yarns sells a fair amount of natural yarns) in these enormous vats. They were empty the day I visited, but I did spy some recently dyed secret yarn nearby. (Of course, I can't share secret yarn pics!)

Yarn then needs to head to the drying room. Which was filled with yarn that was relaxing before it goes on to the next step...

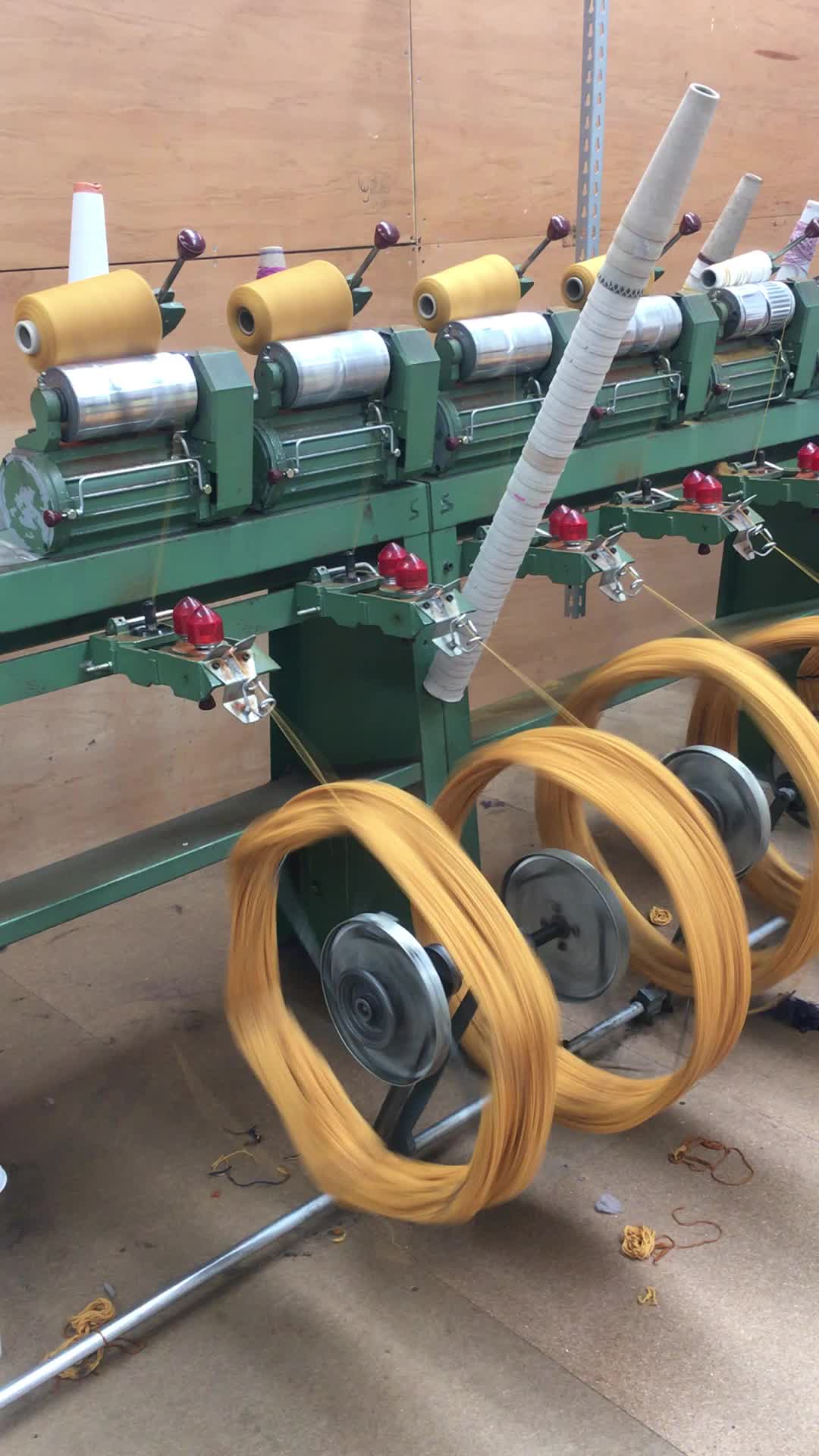

From large hanks of yarn, it goes onto this machine that transfers the wool onto cones. This machine works FAST, and someone is constantly replacing the hanks. Again, you can click that last one to load a short video of it working.

It seemed strange at first that they would take these hanks that are practially skeins and make them into cones. But I learned that cones are needed to go on the ball winder. That makes sense!

Even with all these photos, I wish I had taken more. I wandered through aisles of wool, explored knitting and crochet samples of many of Blacker Yarns' free patterns, and was in general, like in kid in a wooly candy store.

Thank you, Katie, for giving me the tour! And for helping me add to my list of knitting projects that I must make!

Mollie,

ReplyDeleteSounds like you had the best time ever. I, personally, would love to see you post about your trip whether or not there were any crafting or crafts in it. Where else did you go in England?

Maureen

The time was split between Devon/Cornwall and London. It was all so beautiful!

DeleteThat. Is. Amazing.

ReplyDeleteIt's nice to see how it all looks from the beginning

ReplyDelete